-

Wall sound insulation with 100% sound

## Walls of sound insulation With the expansion of the apartment and the increase in urban density, annoying sounds have become a new problem for all residents and neighbors Humans, despite the many everyday concerns and work and job stress, no longer tolerate the disturbing neighbor and abnormal voices, and at least at home relax, and fortunately this problem can be solved with a proper choice. ### Walls of the wall ** Guaranteed wall insulation ** German URSA brand and ISOVER France (nanotechnology) with 100% different insulators such as stone wool and glass wool that mold and smell high and have a very poor sound in practice. Have all the European CE standards ** The room wall insulation ** Rooms are one of the spaces to be insulated in the building. You can use the best sound insulation in your space to suit your needs. These insulators are used in a variety of rooms such as bedrooms, study room, baby room, office room, hotel room and more. The wall of the room or lounge can be used to insulate the room. The Voice Insulation Design and Implementation Company must first visit the visiting site and precisely determine the needs of the applicant. After examining the existing conditions, proper insulation can be installed for guaranteed sound. [Sound insulation Wall] (https://idehpoyan.com/%25D8%25B9%25d8%25A7%25DB%258C%25D9%2582- 155d8%25B5%25d8%25af% 25d8%25a7%25da%25AF 25DB%258C%25d8%25d8%25d8%25db%25d9%25d9%25d8%25d8%25d8%25d8%25d8%25d8%25

Building Materials Tehran -

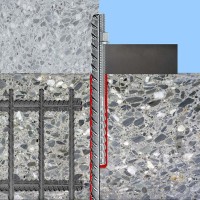

vapor barrier | roof insulation

Your roof is a very important part of your home that plays an essential role in protecting you and Your building may be exposed to different environmental factors in different seasons of the year Let's face it. When moisture on the roof in contact with the heat of the sun It is placed, it moves inward. In conventional ceilings, this moisture through Steam is directed inside. To prevent moisture penetration into thermal insulation It is mandatory to use a vapor barrier. Without a vapor barrier layer, moisture transferred in warm air In the residential space inside, it may spread in thermal insulation. Also in months In winter, when there is a possibility of condensation, rainwater may also enter the structure of the building and cause an increase in the level of humidity in the roof. The release of water vapor in the air is possible is lead to the formation of condensate that, in turn, may significantly on affect the performance of the insulation layer • Condensation can cause great damage to the roof structure. . By creating an efficient protection, it can be ensured that the moisture in the air It cannot enter the ceiling from living rooms and damage it. In fact, the vapor barrier layer not only prevents the penetration of moisture into the insulation slow, but also prevents air flow through the thermally insulated roof. If the internal use of your building is wet, such as a room Swimming pool, kitchen, shower room, etc., hot and humid air can enter through the separating walls, chimney, and electrical or plumbing holes. The roof will open. • It should be noted that the use of a vapor barrier layer under all coverings of sloping roofs such as shingles, tiles, pottery, sheets, etc., to prevent It is necessary to create condensation and improve the performance of thermal insulation and increase the lifespan of building materials.

Building Materials Tehran -

Floor rubble for flooring

Floor stone (focusing on application and Mashhad) Suggested title: Considerations for installing floor stone in open spaces and landscaping\r\nWhen using crushed stone for landscaping in Mashhad, in addition to visual beauty, special attention should be paid to the proper slope for water drainage. The use of sanded or processed materials (such as crushed stone) in areas where there is water accumulation increases the useful life of the path. The quality of mortaring is also a decisive factor in preventing the movement of stones in the long term.\r\nThis content is for technical information purposes only.\r\nSpecialized supplier: Hossein Najafi, http://sangnajafi.com/

Building Materials Tehran -

قیمتگذاری هر متر مربع سنگ لاشه با کمترین حاشیه سود

به پایان روزهایی خوش آمدید که مجبور بودید برای درک هزینه واقعی، چندین فاکتور پیچیده را رمزگشایی کنید. ما قیمت هر متر مربع سنگ لاشه را بر اساس وزن خالص، نوع سنگ (سفید، سبز، آذرین) و ضخامت استاندارد، به صورت کاملاً شفاف به شما اعلام میکنیم. هیچ هزینه پنهانی در کار نیست؛ فقط کیفیت مستقیم معدن. ## فاکتور رسمی با جزئیات کامل متراژ و نوع سنگ برای پروژههای اداری و مناقصات، ارائه فاکتور رسمی با ذکر دقیق متراژ مصرفی، نوع فرآوری و مبدأ استخراج الزامی است. ما تمامی مستندات فنی و مالی لازم را برای ارائه به کارفرمایان محترم فراهم میآوریم. مقایسه کنید: بهترین کیفیت در قبال قیمتی که میپردازید قیمت ما را با دیگران مقایسه کنید، اما هرگز کیفیت استخراج و سورتبندی ما را با یک سنگ مالون سنگ لاشه معمولی مقایسه نکنید. ما تضمین میکنیم که با همین قیمت رقابتی، بالاترین درجه سختی و کمترین میزان دورریز را تجربه خواهید کرد. تأمین کننده تخصصی: حسین نجفی،http://sangnajafi.com/

Building Materials Tehran